A car-sense belt-sense detection integrated machine

The utility model discloses an all-in-one machine for vehicle sense and belt sense detection, which comprises a support plate. The upper surface of the support plate is fixedly connected with two sets of wheel fixing frames, and the front surface of the support plate and the back surface of the support plate are fixedly connected with two A first connecting plate, the bottom surface of each first connecting plate is fixedly connected with a first clamping block, two sets of first hydraulic rods are placed under the supporting plate, and the first hydraulic rod is provided with the power provided by the first clamping block. The block and the first connecting plate can make the support plate tilt left and right, and the support plate can be tilted left and right while driving the detection to tilt left and right. The fixed plate is tilted up and down in the left and right directions, which can simulate the situation of the vehicle when it encounters different road conditions, and avoid the test of the car in a single direction, which not only increases the detection time, reduces the detection efficiency, but also increases the detection machine. cost of use.

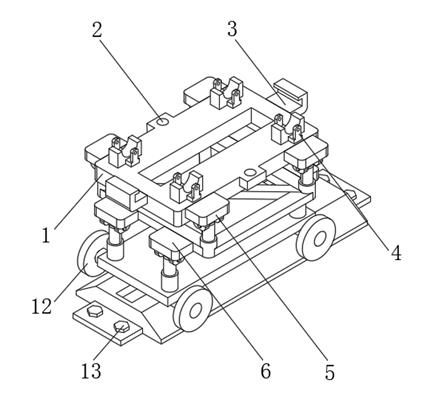

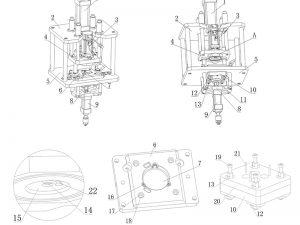

- An all-in-one machine for vehicle sense and belt sense detection, comprising a support plate (1), characterized in that: the upper surface of the support plate (1) is fixedly connected with two sets of wheel fixing frames (4), and the support plate (1) Two first connecting plates (5) are fixedly connected to the front of the support plate (1) and the back of the supporting plate (1), and a first clamping block (16) is fixedly connected to the bottom surface of each first connecting plate (5), so Two groups of first hydraulic rods (14) are placed under the support plate (1), and the output ends of each group of the first hydraulic rods (14) are fixedly connected to the interior of the first clamping block (16). The outer surfaces of the first hydraulic rods (14) are both fixedly connected with a fixing plate (15), and two second connecting plates (6) are fixedly connected to one side of the two fixing plates (15) away from each other. , the bottom surface of each second connecting plate (6) is fixedly connected with a second clamping block (19), a bottom plate (20) is placed under the supporting plate (1), and the upper surface of the bottom plate (20) Two groups of second hydraulic rods (21) are fixedly connected, and the output ends of each group of the second hydraulic rods (21) are fixedly handed over to the inside of the second clamping block (19) through a pin shaft.

- The all-in-one vehicle sense and belt sense detection machine according to claim 1, characterized in that: a base (7) is placed under the bottom plate (20), and a chute (9) is opened inside the base (7). ), a sliding block (8) is clamped inside the chute (9), the upper surface of the sliding block (8) is fixedly connected with the bottom surface of the bottom plate (20), and the left side of the base (7) A positioning plate (10) is fixedly connected to the right side of the base (7).

- The all-in-one vehicle sense and belt sense detection machine according to claim 1, wherein two sliding wheels (12) are fixedly connected to the front surface of the bottom plate (20) and the back surface of the bottom plate (20), and two sets of A stabilizer (18) is fixedly and fixedly connected to the outer surface of the first hydraulic rod (14).

- The all-in-one vehicle sense and belt sense detection machine according to claim 1, characterized in that: the upper surface of the support plate (1) is provided with two fixing through holes (2), The left side and the right side of the support plate (1) are fixedly connected to the limiting plate (3).

- The all-in-one vehicle sense and belt sense detection machine according to claim 1, characterized in that: two stabilizing plates (17) are fixedly connected to the outer surfaces of the two sets of the first hydraulic rods (14), and the two The mutually close side surfaces of the stabilization plates (17) are respectively fixedly connected to the front surface of the stabilization frame (18) and the back surface of the stabilization frame (18).

- The all-in-one vehicle sense and belt sense detection machine according to claim 2, characterized in that: two threaded through holes (11) are formed on the upper surface of each of the positioning plates (10), and each of the threaded through holes (11). Fixing bolts (13) are threadedly connected inside the through holes (11), and the bottom end of each fixing bolt (13) penetrates through the threaded through holes (11) and extends below the positioning plate (10).

The all-in-one vehicle sense and belt sense detection machine according to claim 1, characterized in that: two spring plates (24) are fixedly connected to the inner side walls of the chute (9), and the two spring plates (24) ) are fixedly connected with buffer springs (23) on one side close to each other, and both ends of the two buffer springs (23) close to each other are fixedly connected with a backing plate (22).

A car-sense belt-sense detection integrated machine

Technical Field

The utility model relates to the field of automobile detection, in particular to an integrated machine for vehicle sense and belt sense detection.

Background Technique

Automobile inspection is an inspection to determine the technical condition or working ability of the automobile. During the use of the automobile, with the extension of the use time, its parts gradually wear, corrode, deform, age, and the lubricating oil deteriorates, etc., which causes the matching pair gap to become larger. , causing loose movement, vibration, noise, air leakage, water leakage, oil leakage, etc., resulting in a decline in the technical performance of the car, and after the production of the vehicle is completed, the vehicle sense detection is also required to detect the comfort of the car when driving. , especially the induction effect of seat belts, is the top priority in testing.

The existing vehicle inspection machine can only detect a single performance of the car, but cannot detect multiple performances of the car, which not only increases the inspection time, reduces the inspection efficiency, but also increases the use cost of the inspection machine. Therefore, those skilled in the art provide an all-in-one machine for vehicle sense and belt sense detection, so as to solve the problems raised in the above-mentioned background art.

Utility Model Content

The purpose of the present utility model is to provide an integrated machine for vehicle sense and belt sense detection, so as to solve the problems raised in the above-mentioned background art.

To achieve the above object, the utility model provides the following technical solutions:

It includes a support plate, the upper surface of the support plate is fixedly connected with two sets of wheel fixing frames, the front surface of the support plate and the back surface of the support plate are fixedly connected with two first connection plates, each of the first connection plates A first clamping block is fixedly connected to the bottom surface of the supporting plate, and two sets of first hydraulic rods are placed under the support plate, and the output ends of each group of the first hydraulic rods are fixedly connected with the interior of the first clamping block. The outer surfaces of the first hydraulic rods are both fixedly connected with a fixed plate, and one side of the two fixed plates away from each other is fixedly connected with two second connecting plates, and the bottom surface of each second connecting plate is A second clamping block is fixedly connected, a bottom plate is placed under the support plate, two sets of second hydraulic rods are fixedly connected to the upper surface of the bottom plate, and the output ends of each set of the second hydraulic rods are connected to the first hydraulic rod through a pin shaft. The internal fixed handover of the two card blocks.

As a further solution of the present invention: a base is placed under the bottom plate, a chute is opened inside the base, a sliding block is clamped inside the chute, and the upper surface of the sliding block is connected to the bottom surface of the bottom plate. Fixed connection, the left side of the base and the right side of the base are fixedly connected with a positioning plate.

As a further solution of the present invention, two sliding wheels are fixedly connected to the front surface of the bottom plate and the back surface of the bottom plate, so that the device can move more quickly, and the outer surfaces of the two sets of the first hydraulic rods are fixed together. Fixed connection with stabilizer.

As a further solution of the present invention, the upper surface of the support plate is provided with two fixing through holes, and the left side of the support plate and the right side of the support plate are fixedly connected to the limiting plate.

As a further solution of the present utility model: two stabilizing plates are fixedly connected to the outer surfaces of the two sets of the first hydraulic rods, and the side surfaces of the two stabilizing plates that are close to each other are respectively connected with the front surface of the stabilizer frame and the front surface of the stabilizer frame. Fixed connection on the back.

As a further solution of the present utility model: the upper surface of each of the positioning plates is provided with two threaded through holes, and the interior of each of the threaded through holes is threadedly connected with fixing bolts. The bottom ends all pass through the threaded through holes and extend below the positioning plate.

As a further solution of the present invention, two spring plates are fixedly connected to the inner side wall of the chute, and buffer springs are fixedly connected to one side of the two spring plates that are close to each other, and the two buffer springs are close to each other. One end is fixedly connected with a backing plate.

Static Seat Belt

Static Seat Belt Universal 2-Point Seat Belt

Universal 2-Point Seat Belt Universal 3-Point Seat Belt

Universal 3-Point Seat Belt Baby Seat Fittings / Holder

Baby Seat Fittings / Holder Seat Belt Extender

Seat Belt Extender Wheelchair Seatbelt

Wheelchair Seatbelt Racing Seat Belt

Racing Seat Belt Seat Belt Tongues/Buckles

Seat Belt Tongues/Buckles Anchorage Rings

Anchorage Rings Anchorage Plate

Anchorage Plate Seat Belt Adjuster

Seat Belt Adjuster