Pretensioner Safety Belt Retractor Claims

- Pre-tightening retractor, including pre-tightening bracket, gas generator, rack, gear, vehicle-mounted wiring harness, reel, force limiting shaft, frame, left base and right base, characterized in that: One end of the gas generator is connected with the car body harness, and the other end is installed under the pre-tensioning bracket by means of riveting. The pre-tensioning bracket is also equipped with a rack and a gear, and the rack can slide up and down in the pre-tensioning bracket. And form a sealed cavity inside the pre-tensioning bracket with the gas generator, the gear is meshed with the rack, the left and right ends of the gear are respectively connected with the left base and the left side of the force limiting shaft, and the left base is installed in the pre-tensioning bracket. On the tightening bracket, the right base is installed on the frame, the right side of the force limiting shaft is connected to the right base, the force limiting shaft is located inside the reel and is coaxial with the reel, and the reel is installed on the Frame.

- The pre-tightening retractor according to claim 1, wherein a sealing ring is installed between the lower end of the rack and the inner wall of the pre-tightening bracket.

Summary of Instruction

The utility model discloses a pre-tightening retractor, which comprises a mounting frame, on which a belt winding shaft is rotatably arranged, one end of the winding shaft is connected with a coil spring, and the two winding shafts Both sides are connected with a ratchet, a swinging piece is provided on the mounting frame, and the swinging piece is connected with the first elastic resetting piece, and the swinging piece is provided with a protrusion that can be matched and compressed with the two ratchets. It is characterized in that it further includes a limit swing arm, the middle of the limit swing arm is hinged on the swing member, a first spring is tightly arranged between one end of the limit swing arm and the swing member, and the swing member is A limit protrusion capable of abutting the limit swing arm is provided, the mounting frame is arranged in the outer cover, and an adjustment bolt is screwed on the outer cover, and the adjustment bolt can be pressed against the limit swing arm . The utility model has the advantages of simple structure, reasonable design, convenient installation, low cost and light weight.

Manual

Pretensioner Safety Belt Retractor

Technical field

The utility model relates to safety belt equipment, in particular to a pre-tightening retractor.

Background of technique

The pre-tightening retractor is a more commonly used product in the current vehicle market, and it plays a decisive role in the safety of the occupants in the occupant restraint system. The pre-tightening retractor is mainly used in the front row of the vehicle, and is used in conjunction with the airbag. With the development of the automobile industry, the use of pre-tightening retractors in low-end and medium-end models has also increased significantly, accompanied by the requirements for production and installation cost control. The existing structure uses a threaded sleeve to connect with the thread at one end of the pre-tightening bracket to fix the gas generator. Such a product has the problems of high cost, difficult installation and heavy weight.

Summary of the invention

In view of the shortcomings of the background technology, the technical problem to be solved by the present utility model is to provide a retractor with simple structure and reasonable design, which can adjust the initial pull-out amount of the seat belt according to different vehicle models and use environments.

For this reason, the utility model is realized by adopting the following scheme:

The pre-tightening retractor includes a pre-tightening bracket, a gas generator, a rack, a gear, a car harness, a reel, a force limiting shaft, a frame, a left base and a right base, and is characterized in that: the gas generator One end of the device is connected with the car body harness, and the other end is installed at the lower part of the pre-tensioning bracket by means of riveting. The pre-tensioning bracket is also equipped with a rack and a gear, and the rack can slide up and down in the pre-tensioning bracket and interact with The gas generator forms a sealed cavity inside the pre-tensioning bracket, the gear is meshed with the rack, the left and right ends of the gear are respectively connected to the left base and the left side of the force limiting shaft, and the left base is installed on the pre-tensioning bracket The right base is mounted on the frame, the right side of the force limiting shaft is connected to the right base, the force limiting shaft is located inside the reel and is coaxial with the reel, and the reel is mounted on the frame .

A sealing ring is installed between the lower end of the rack and the inner wall of the pre-tensioning bracket.

By adopting the above technical solution, the utility model has the advantages of lengthening one end of the pre-tightening bracket, so that the gas generator is lined into the pre-tightening bracket, and then riveting one end of the pre-tightening bracket by a rotary riveting machine to make the gas generator fixed. This installation method cancels the thread of the threaded sleeve and the pre-tightening bracket during the general installation, reduces the cost and reduces the weight. At the same time, it avoids the situation that the screw sleeve is manually installed manually and the gas generator shakes due to improper installation during the installation process. The spin riveting machine is used to control the riveting pressure, which greatly improves the consistency of the product, makes the installation easier, and improves the product quality at the same time, which provides favorable conditions for better meeting the requirements of the automotive market.

Description of the drawings

The utility model has the following drawings:

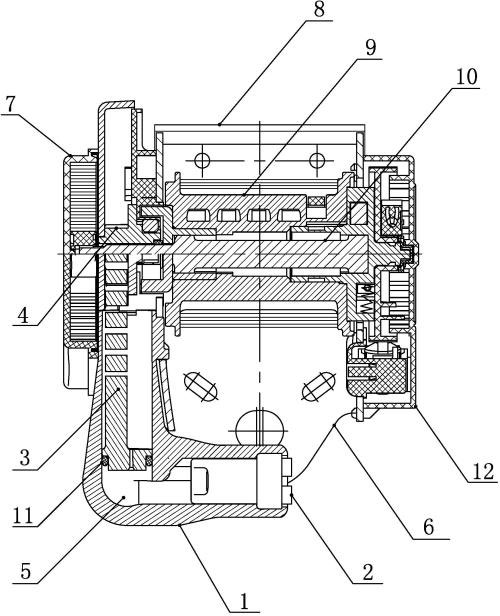

Figure 1 is a schematic diagram of the structure of the utility model.

Detailed ways

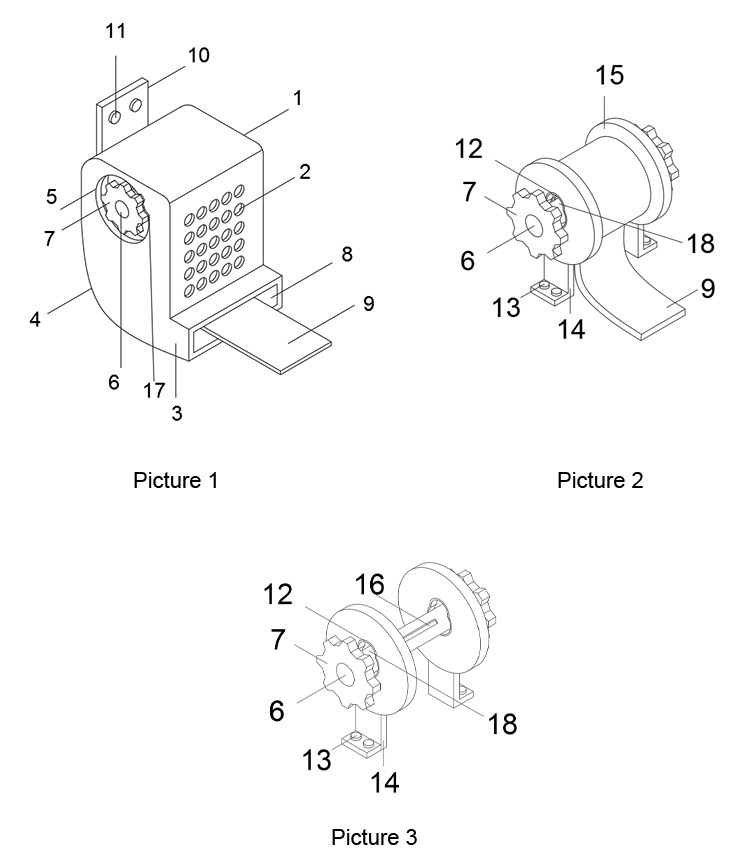

As shown in the figure, the pre-tightening retractor disclosed by the utility model includes a pre-tightening bracket 1, a gas generator 2, a rack 3, a gear 4, a vehicle-mounted wiring harness 6, a reel 9, a force limiting shaft 10, and a frame 8. The left base 7 and the right base 12. One end of the gas generator 2 is connected with the car body harness 6 and the other end is installed at the lower part of the pre-tightening bracket 1 by means of riveting. A rack 3 and a gear 4 are also installed on the pre-tensioning bracket 1. The rack 3 can slide up and down inside the pre-tensioning bracket 1 and form a sealed cavity 5 with the gas generator 2 inside the pre-tensioning bracket. A sealing ring 11 is installed where the lower end of the rack 3 is in contact with the sealed cavity 5. The gear 4 meshes with the rack 3, the left and right ends of the gear 4 are respectively connected to the left base 7 and the left side of the force limiting shaft 10, and the right side of the force limiting shaft 10 is connected to the right base 12. The left base 7 is installed on the pre-tensioning bracket 1, and the right base 12 is installed on the frame 8. The force limiting shaft 10 is located inside the reel 9 and is coaxial with the reel 9. The reel is installed on the frame 8.

The working process of the pre-tightening retractor of the present invention is as follows: After the car body collides, the gas generator 2 ignites after receiving the car body current signal transmitted from the car body harness 6, and the gas generator 2 generates a large amount of high-pressure gas and enters it. In the sealed cavity 5 formed with the rack 3, the high-pressure gas pushes the rack 3 to move, the rack 3 drives the gear 4 meshed with it to rotate, and the gear 4 drives the force limiting shaft 10 connected to it to rotate. The pulley 9 rotates together to make the retractor work.

With this structure of the utility model, one end of the pre-tightening bracket is lengthened to make the gas generator lined into the pre-tightening bracket, and then one end of the pre-tightening bracket is spun riveted by a spin riveting machine to fix the gas generator. This installation method cancels the thread of the threaded sleeve and the pre-tightening bracket during the general installation, reduces the cost and reduces the weight. At the same time, it avoids the situation that the screw sleeve is manually installed manually and the gas generator shakes due to improper installation during the installation process. The spin riveting machine is used to control the riveting pressure, which greatly improves the consistency of the product, makes the installation easier, and improves the product quality at the same time, which provides favorable conditions for better meeting the requirements of the automotive market.